The benefits of installing energy storage in steel plants

Aug 29, 2024

1. Reduce electricity bills

By building energy storage systems in steel plants, companies can charge during off-peak hours and discharge during peak hours, effectively adjusting peak and valley power consumption and reducing electricity bills. Especially in areas with large peak-to-valley electricity price differences, the economic benefits of energy storage systems are more significant.

2. As backup power supply and emergency power supply

The energy storage system can also be used as a backup power supply and emergency power supply system for steel plants. It can quickly switch to emergency power supply mode when the power grid fails or loses power, ensuring the normal operation of key equipment and avoiding production interruptions and economic losses.

3. Promote green production and low-carbon transformation

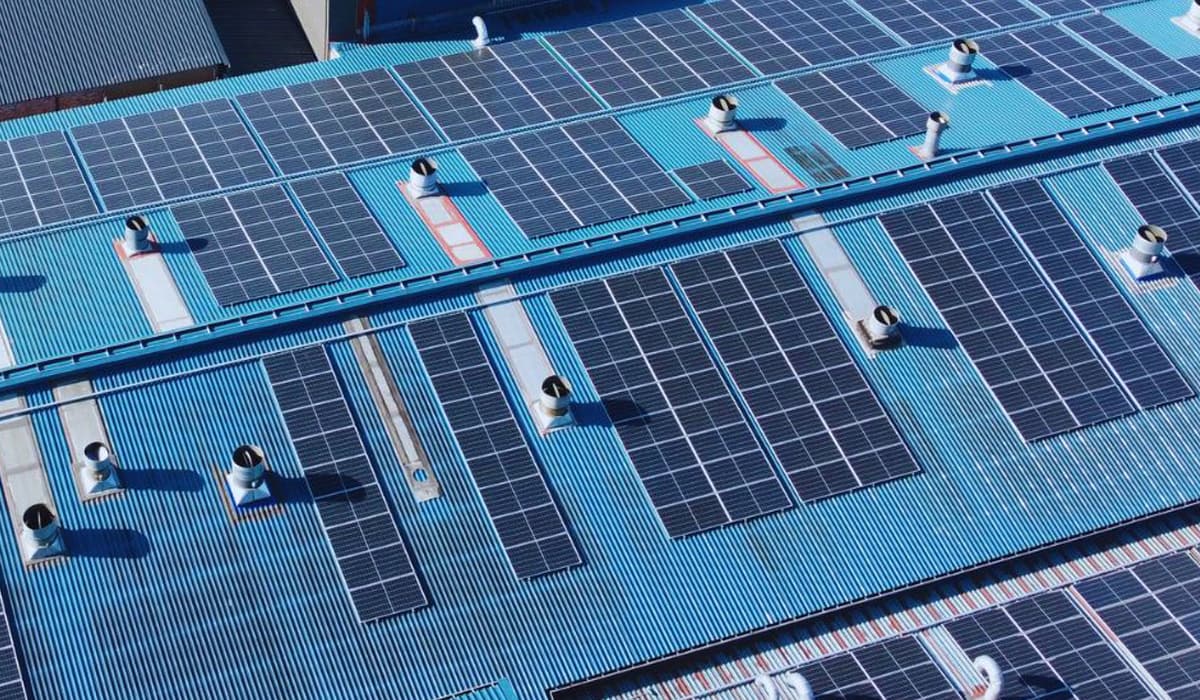

Energy storage systems can be combined with renewable energy sources such as distributed photovoltaics to improve the utilization of green power and reduce dependence on traditional fossil energy. This not only helps steel companies reduce carbon emissions, but also meets the requirements of the national "double carbon" strategy and promotes the green transformation and sustainable development of companies.

4. Enjoy policy subsidies and accelerate the payback cycle

In recent years, national and local governments have introduced user-side energy storage subsidy policies, providing strong policy support for steel companies to invest in energy storage systems. The support of subsidies will further shorten the payback cycle of energy storage projects and improve the economic benefits of the project.

Taking Jiangsu, a major steel province, as an example, a Jiangsu company engaged in the production and manufacturing of oriented silicon steel has built a 20MWh industrial and commercial energy storage power station. Based on Jiangsu's peak-valley electricity price policy, the energy storage power station significantly reduces the electricity cost for enterprises through the "low valley charging, peak discharge" operation mode. Under the dual value of cost reduction and carbon reduction, it is calculated that the 20MWh energy storage power station can also bring nearly 10 million yuan of economic benefits to the enterprise during its entire life cycle.

The specific installation of energy storage equipment should be calculated based on data such as electricity bills and load daily power curves. It is calculated that if the peak-valley electricity price difference is 0.9 yuan per kilowatt-hour and it runs 640 times a year, if equipped with a 1MWh industrial and commercial energy storage system, the peak-valley arbitrage income in the first year will reach 448,500 yuan. Taking into account the attenuation rate of energy storage equipment, operating efficiency and other issues, the average income over ten years is about 390,000 yuan. Combined with the local energy storage subsidy policy, if the company invests by itself, it can recover its investment in about four years.

Steel Plant Energy Storage Case

Nowadays, more and more leading steel companies are beginning to deploy energy storage. Large-scale energy storage power stations are built in the factory area to achieve cost reduction, efficiency improvement and low-carbon transformation through peak-valley arbitrage and green electricity utilization.

In June this year, the groundbreaking ceremony for the 30.09MW/60.18MWh energy storage power station project of Changzhou Oriental Special Steel Co., Ltd. was held.

It is reported that the total investment of the energy storage power station exceeds 70 million yuan, and the core adopts domestic advanced and highly safe lithium iron phosphate battery technology. The project adopts a string energy storage architecture to achieve "one cluster, one management". Each battery cluster is managed by an independent PCS, BMS, and controller to achieve full charging and discharging of each cluster. At the same time, by optimizing the strategy of independent control of charging and discharging, the overall online rate of the system is improved. The energy storage system will significantly reduce the high electricity purchase cost of enterprises every year, achieving the dual value of cost reduction and carbon reduction. In April 2024, China Huaneng's first large-scale user-side energy storage project-Huaneng Longteng Special Steel 20MW/40MWh user-side energy storage project, achieved full-capacity grid-connected power generation.

It is reported that the project has put into operation 8 sets of 2.5MW/5MWh Sungrow PowerTitan2.0 liquid-cooled energy storage systems. This is the first energy storage power station in China to adopt an "AC/DC integrated" design. The system efficiency is 2%-3% higher than traditional energy storage, marking the official arrival of the "AC storage" era. The project is the first to realize the integrated construction mode of "photovoltaic + energy storage + electricity sales", and is expected to generate 18.57 million kWh of electricity annually. Through the "low-valley charging and peak discharge" mode, two charges and two discharges per day, the high electricity purchase cost of the steel plant is greatly reduced, and the dual value of cost reduction and carbon reduction is achieved. The economic benefits of the power station are estimated to reach 66.47 million yuan.

In May 2023, the 25.2MW/243.3MWh energy storage power station on the user side of Jiangsu Changqiang Iron and Steel Company was successfully put into operation.

It is reported that the total investment of the project is 224 million yuan, covering an area of 11 acres, with a construction period of 6 months and a contract operation period of 15 years. Adopting the "peak shaving and valley filling" and "one charge and one discharge" operation modes and the "valley storage and peak discharge" charging and discharging strategies, it is expected that the daily charging capacity will be 197,000 kWh and the discharging capacity will be 163,000 kWh after commissioning, with an annual discharge capacity of about 57.2 million kWh, which basically realizes the full consumption of users and can effectively realize the "peak shaving and valley filling" of the power grid and alleviate the power supply pressure during peak power consumption. This project is the largest single lead-carbon battery energy storage project demonstration base on the user side in China. After commissioning, it can not only save nearly 4.71 million yuan in electricity costs for Changqiang Steel each year, greatly help the company reduce costs and increase efficiency, and further accelerate the company's green and low-carbon transformation, but also achieve "peak shaving and valley filling", effectively alleviating the operating load of the State Grid during peak power consumption.